I haven't forgotten about this site! Today I cleared out some outdated/irrelevant photos from my Projects page and added some new ones, accompanied by details and videos. Here are the newly-added projects:

Capacitive Volume Sensing

Diceview

Probe-Scope

Open Smart Switch

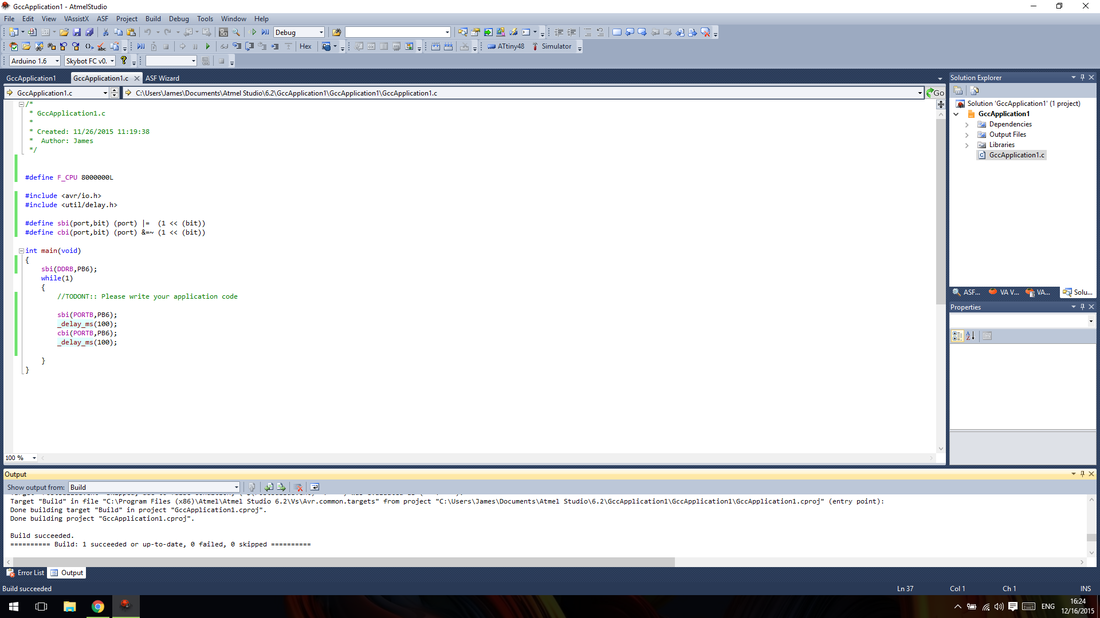

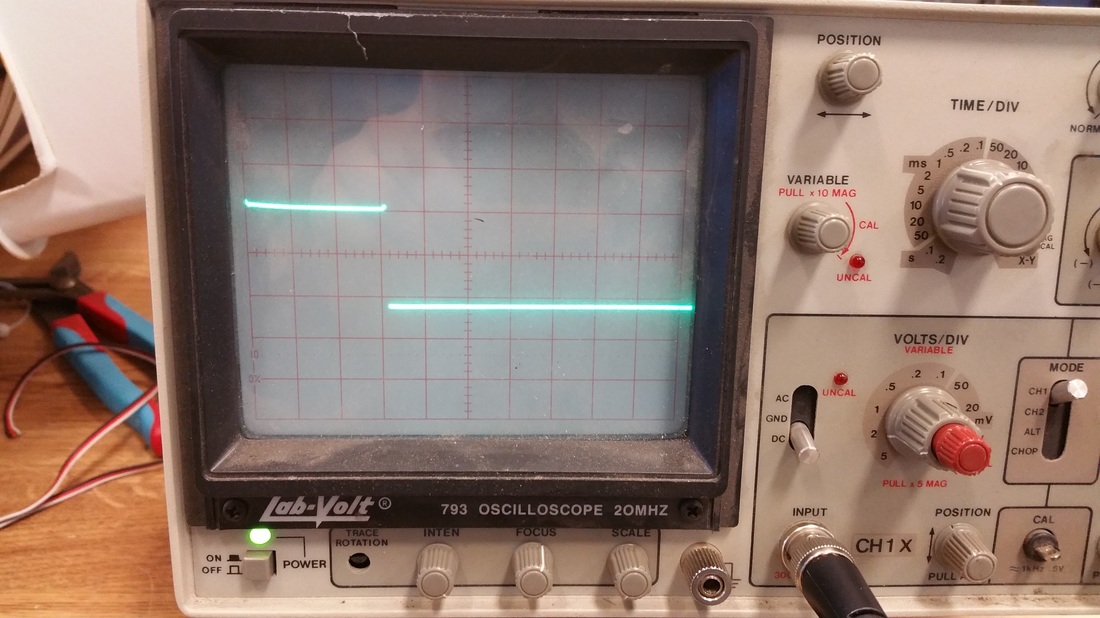

1o1 Oscilloscope

Interview Tester

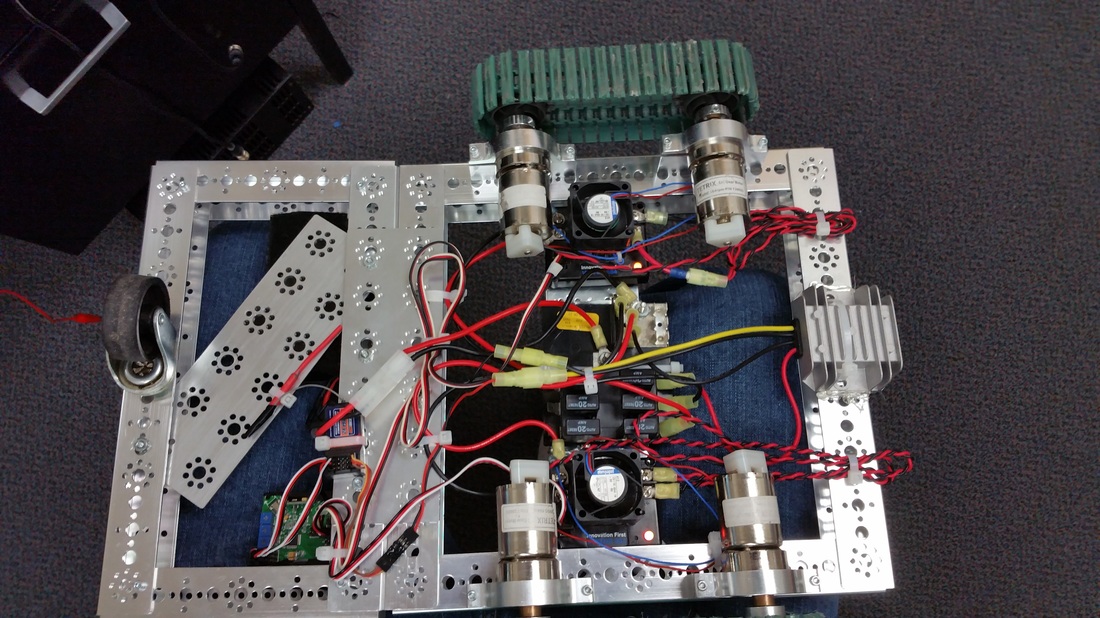

Marcus Engineering

Capacitive Volume Sensing

Diceview

Probe-Scope

Open Smart Switch

1o1 Oscilloscope

Interview Tester

Marcus Engineering

RSS Feed

RSS Feed